10

2022

-

06

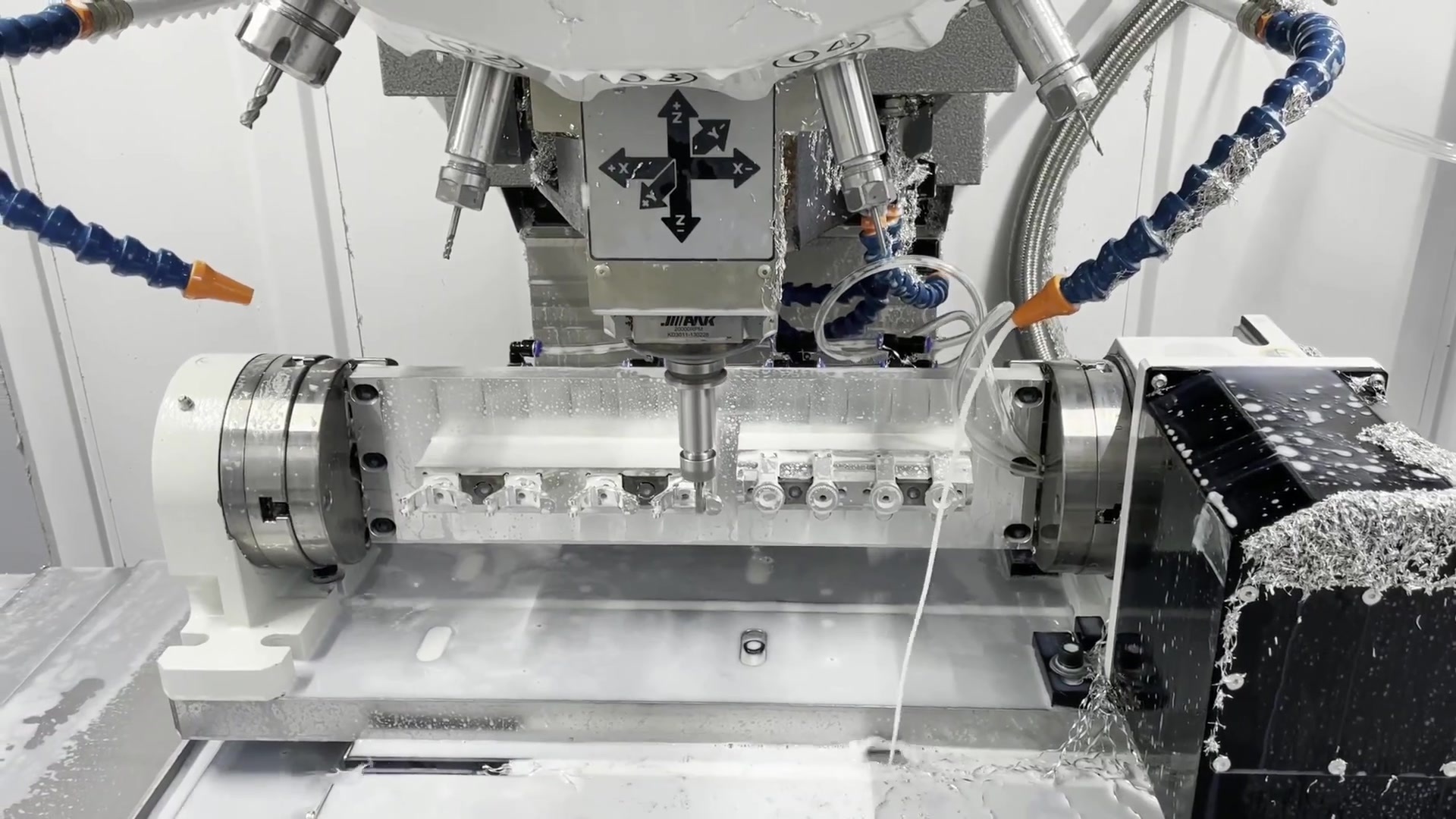

Storage and corrosion prevention of finished metal parts

Most of the factories that produce metal products will have such a problem. The finished metal parts will rust before they can be sold. Smaller factories are fine. Larger ones have thousands of finished products. If the reason remains and needs to be stored for a long time, rust will appear, which is a huge loss to the factory. How to prevent it?

1. Metal protective layer. Use a metal or alloy with strong corrosion resistance to cover the protected metal surface. The methods of covering include electroplating, thermal spraying, vacuum plating, etc. According to the electrochemical properties of anti-corrosion, the protective layer can be divided into anodic protective layer and cathodic protective layer. The standard electrode potential of the anode protection layer metal is lower than that of the base metal

2. Change the storage space of finished metal, store finished metal parts in a place with low humidity in dry air, avoid contact with water and avoid collision.

3. Non-metallic protective layer. Apply corrosion-resistant non-metallic substances to the metal surface of metal products, such as metal anti-rust wax, paint, spray paint, enamel, ceramics, glass, asphalt, polymer materials (such as plastic, rubber, polyester), etc.

Under the condition of long-term storage, it is necessary to select better anti-corrosion materials for spraying. Dino metal anti-rust wax can fully meet these needs. When applied to the metal surface, it can ensure that the metal will not rust for 5-10 years, which greatly reduces the cost of the factory. Loss due to long-term storage.

previous page

previous page