10

2022

-

06

Indirect metal 3D printing will make $54 billion in metal parts by 2030

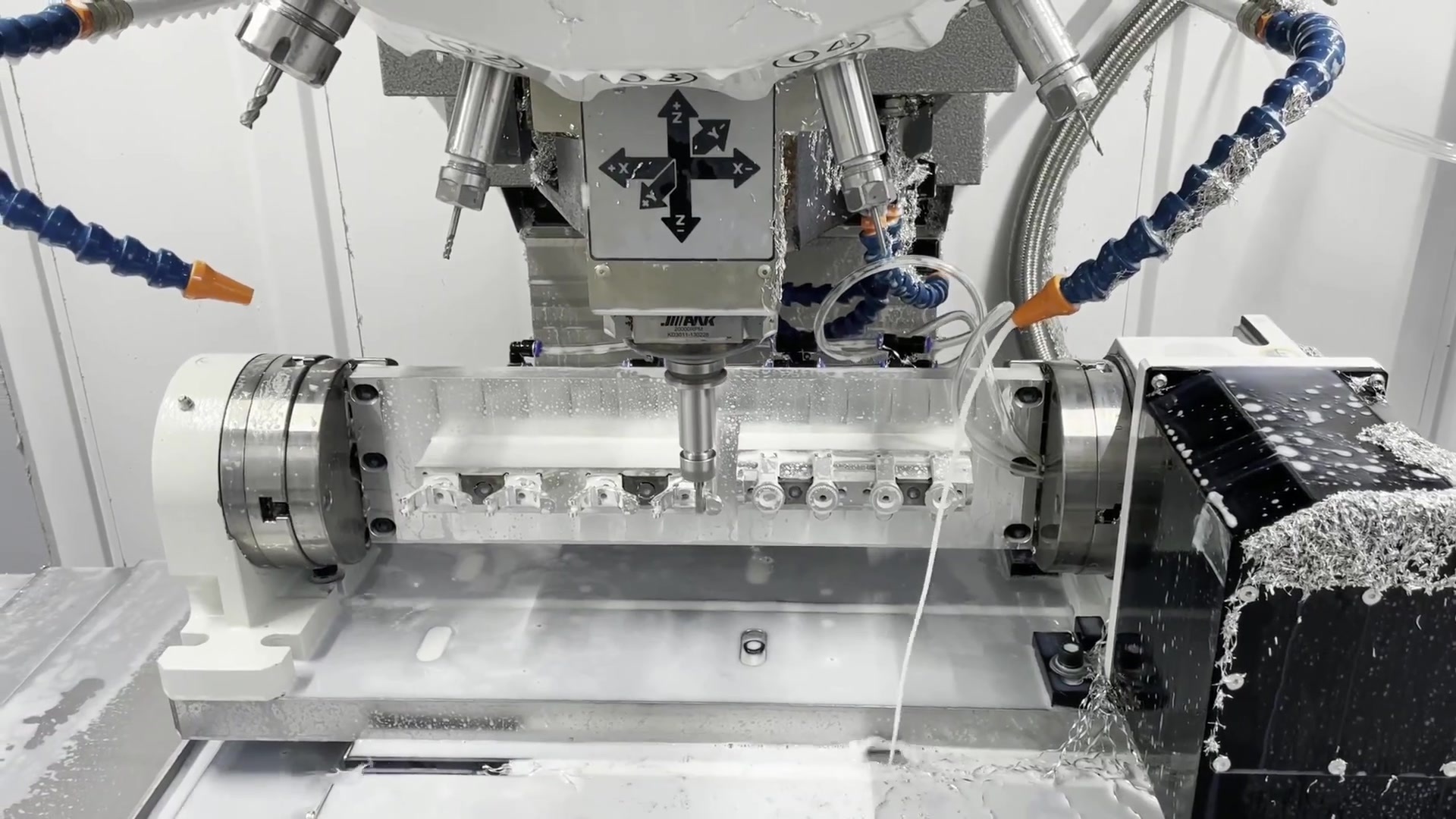

On April 23, 2022, SmarTech released the latest edition of its indirect metal 3D printing report. The report predicts that by 2030, metal binder jetting and extrusion indirect metal printing technology will produce $54 billion (about 350 billion yuan) of parts. Such data means that indirect metal 3D printing will be used in mass production of metal parts at that time.

"This technology is evolving faster than any other field of 3D printing, even outpacing the widely adopted field of metal powder bed fusion (SLM)," SmarTech claims. Companies that have entered this space include established industrial companies such as ExOne/Desktop Metal, Hewlett-Packard, and low-cost extruded indirect metal manufacturers such as 3DGence.

SmarTech analyzes the roots of the industry, the metal binder jetting invented by ExOne to this day. ExOne previously required secondary infiltration of metal-binder jetted parts and thus encountered less market adoption and growth. However, the entry of new players such as HP, Desktop Metal and GE has brought the technology back into focus.

Much of what hinders the application of binder jetting is perception of the technology. To dispel these stereotypes, users can advertise use cases for their production parts. Previous public teasers of the mass use of binder jetting by Volkswagen and Ford have drawn a lot of media attention.

Meanwhile, indirect metal extrusion is also very promising. It's still relatively new and hasn't sparked enthusiasm for it. So far, Desktop Metal and Markforged have built equipment specifically for the process, while BASF and The Virtual Foundry have produced filament for standard desktop 3D printers. In general, these may be used to prototype metal parts, but there may be strong potential for mass-production of terminal parts with a printer fleet.

Indirect metal extrusion as a whole is an exciting direction with low cost, but its full potential is not yet seen. This report combines an extensive database of market forecast data with an extensive analysis of current innovators, strategic considerations, and key applications and adopters of the technology. The price is more than $4000.